32m 4M Sections Column Tower Hydraulic Jack-Up Concrete Placing Boom, Self Climbing Concrete Placing Boom

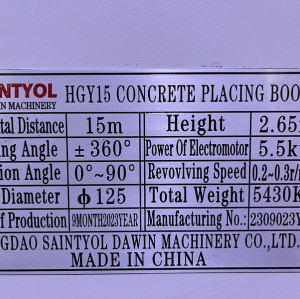

- Model

- HGY32F

Item specifics

- Motor

- 15KW

- Freestanding height (to the joint between the end

- 22.7m

- Placing Radius

- 32m

- Boom Sections

- 4 M

- Certificates

- CE , SafeWork

- Hydraulic System Pressure

- 30 Mpa

Review

Description

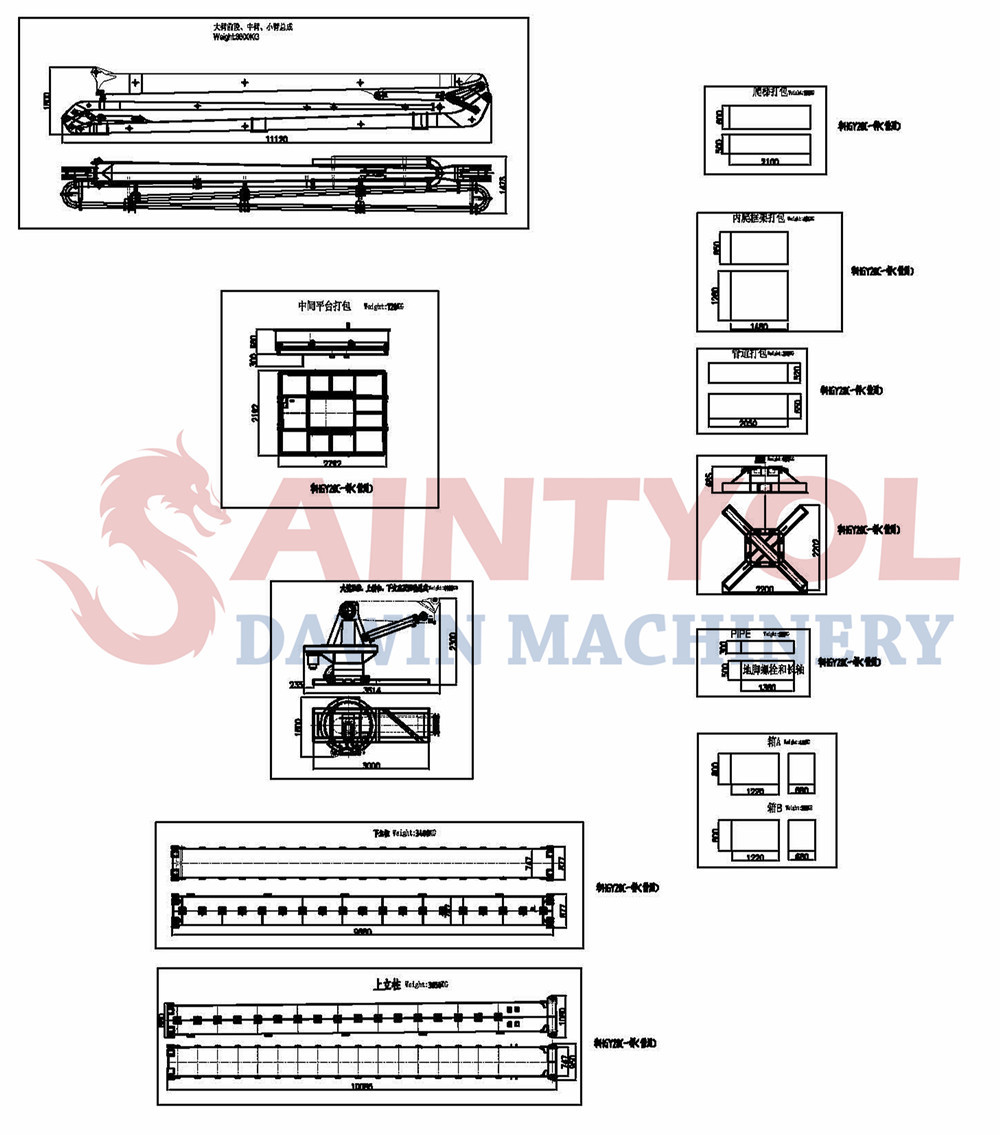

Model | Units | HGY32F | |||

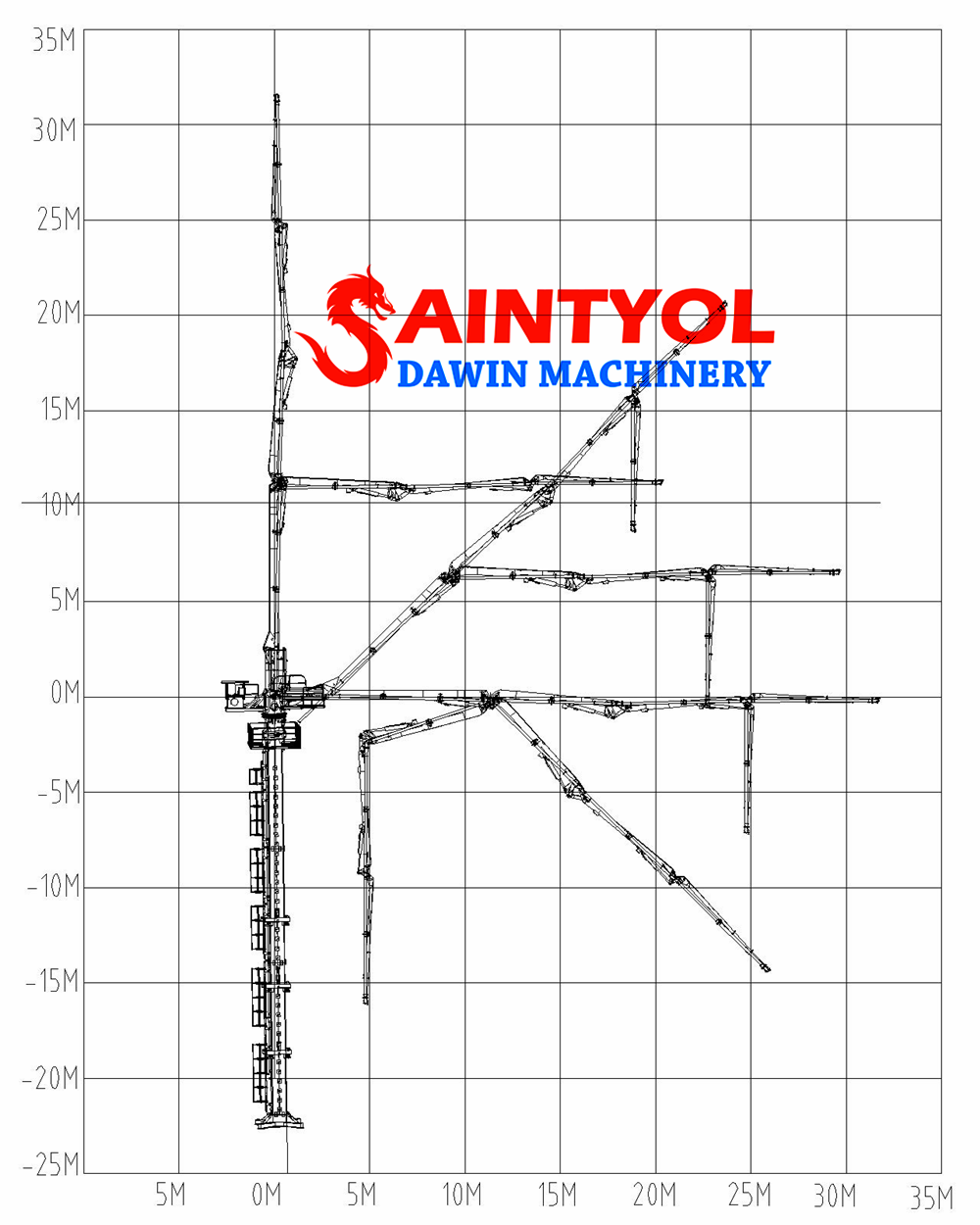

Performance | Max.radius of placing boom | m | 32 | ||

Freestanding height (to the joint between the end of the boom and swivel table) | m | 22.7 | |||

Boom articulation | ° | 400 | |||

Slewing brake | / | always close | |||

Working temperature | ℃ | 0℃~60℃ | |||

Total weight | kg | 24900 | |||

Counter weight | kg | 2900 | |||

Power | / | 380V/50HZ | |||

Motor | Model | / | Y2-160L-4 | ||

Power | kW | 15 | |||

Hydraulic system | Pressure | MPa | 30 | ||

Flux | l/min | 18 | |||

Hydraulic oil | Circumstance temperature 35℃-50℃ | / | L-HM 68 | ||

Circumstance temperature 5℃-35℃ | / | L-HM 46 | |||

Circumstance temperature -15℃-5℃ | / | L-HM 32 | |||

Control mode | / | Short-haul Control /radio remote control | |||

Pipeline cleaning | / | Wet cleaning/Dry cleaning | |||

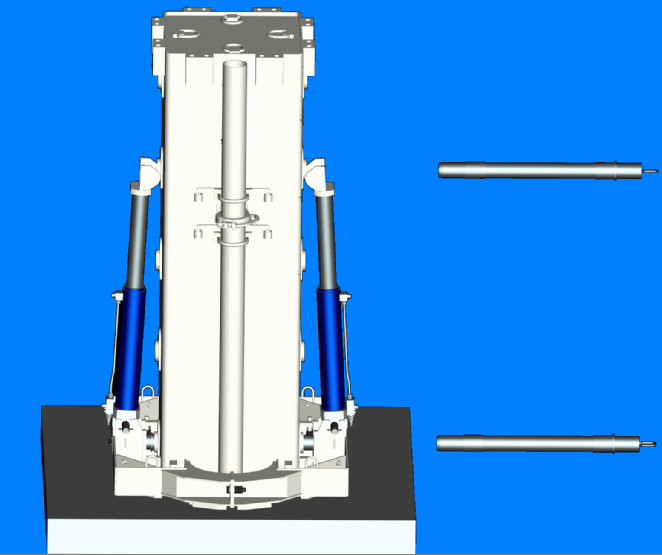

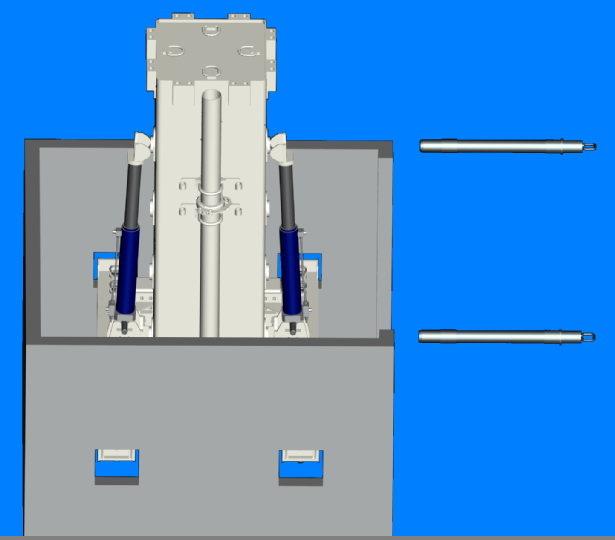

Structure of tower body | / | Tubular column | |||

Section of tower body | m×m | 0.75×0.75 | |||

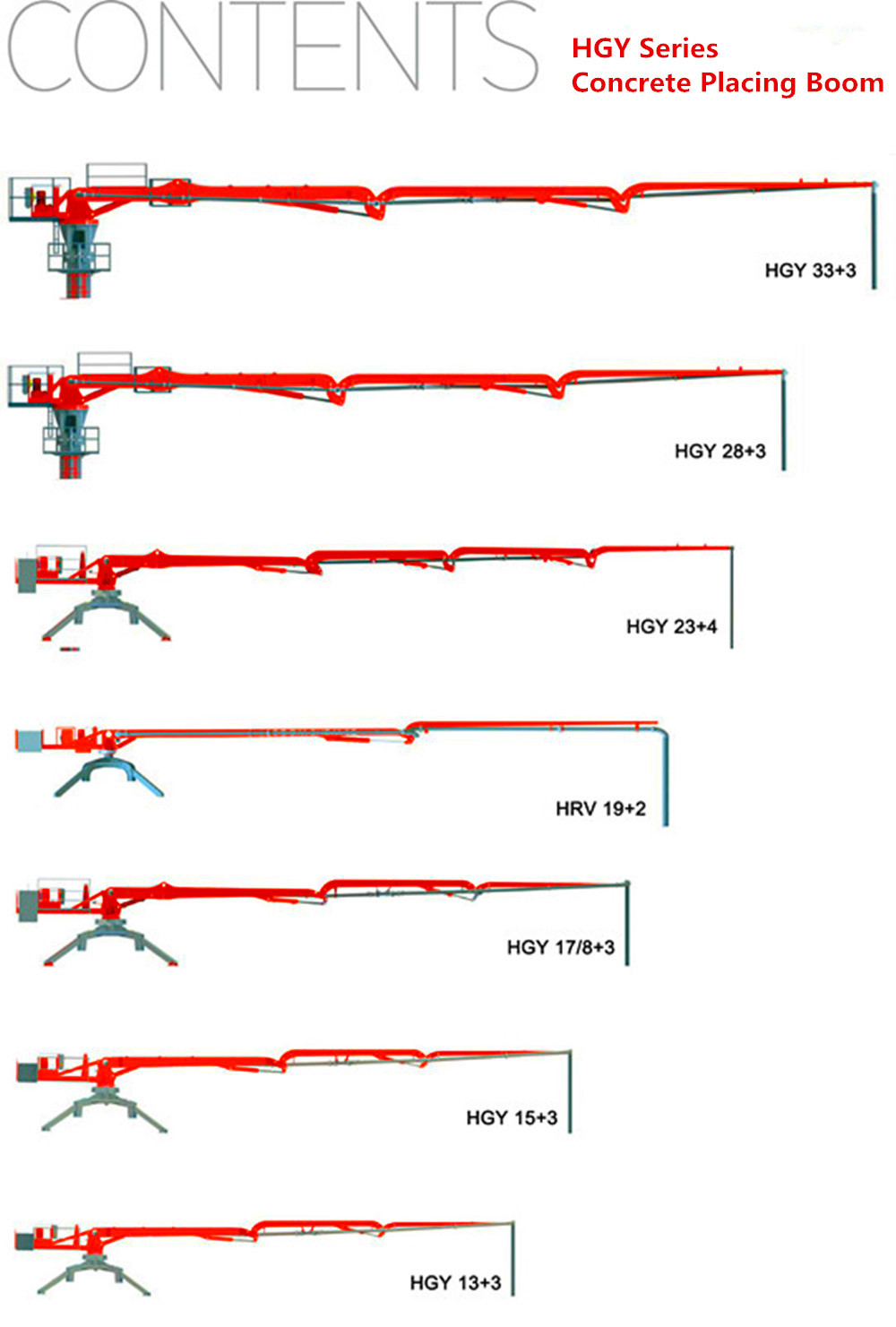

Boom | Shape | / | Four hydraulic foldable arms | ||

Inner diameter of pipeline | mm | DN125 | |||

End hose | ″×mm | 5″×3000 | |||

1st section | Length | m | 9 | ||

Articulation | ° | 0°~82.5° | |||

2nd section | Length | m | 7.65 | ||

Articulation | ° | 0°~180° | |||

3rd section | Length | m | 7.65 | ||

Articulation | ° | 0°~180° | |||

4rd section | Length | m | 7.7 | ||

Articulation | ° | 0°~180° | |||

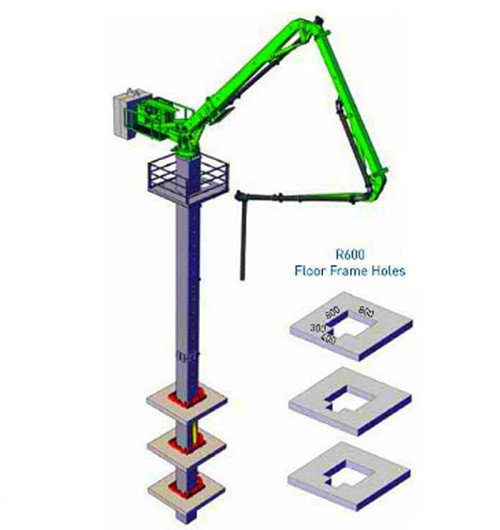

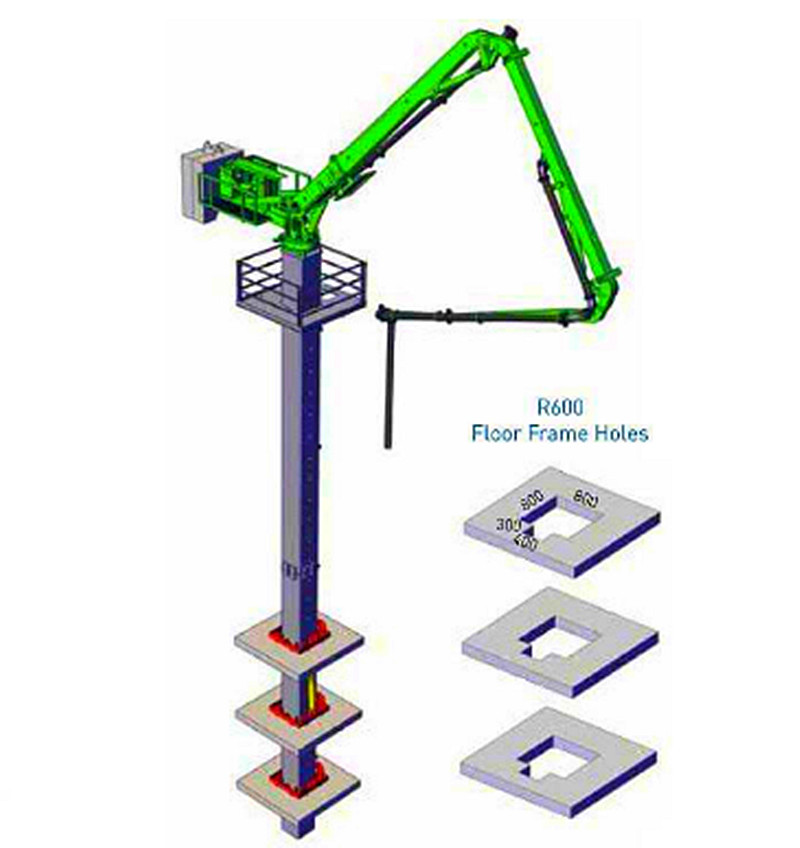

Climbing | Climbing mode | / | By hydraulic cylinder climbing | ||

Interval of climbing | m | 0.52 | |||

Floor frame | / | Hole prepared in floor | |||

Shaft frame | m | Hole prepared in floor2.0~2.7 | |||

Min.Interval of climbing frame | Climbing | m | 3.0 | ||

Placing concrete | m | 6.0 | |||

Rest | m | 6.0 | |||

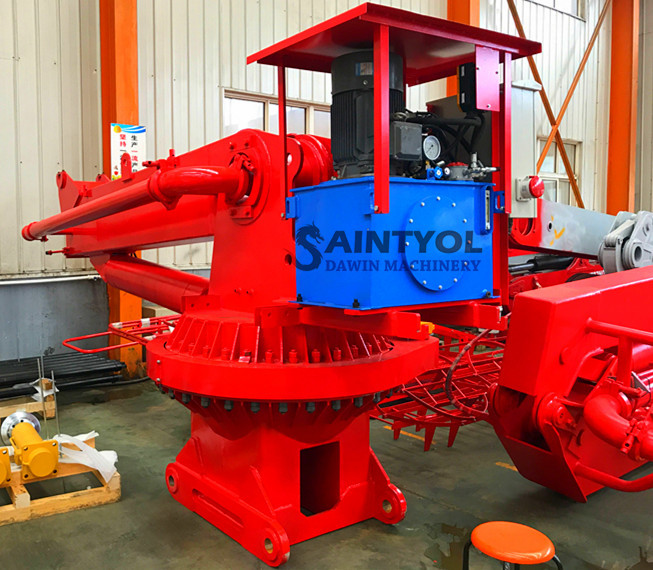

The slewing support is a large-sized bearing which connects the boom and the column, and bears the overturning moment produced by the boom. It is a key component that directly affects the whole machine’s safety. The motor redactor is from Comer in Italy. It is in a high speed rate, and long life span and reliable. The hydraulic motor can rotate the slewing table and the boom 365°through the redactor.