35m 5 Sections Tower Hydraulic Jack-Up Concrete Placing Boom, Self Climbing Concrete Placing Boom

- Model

- HGY32F

Item specifics

- Motor

- 30KW

- Freestanding height (to the joint between the end

- 14.5m

- Placing Radius

- 35m

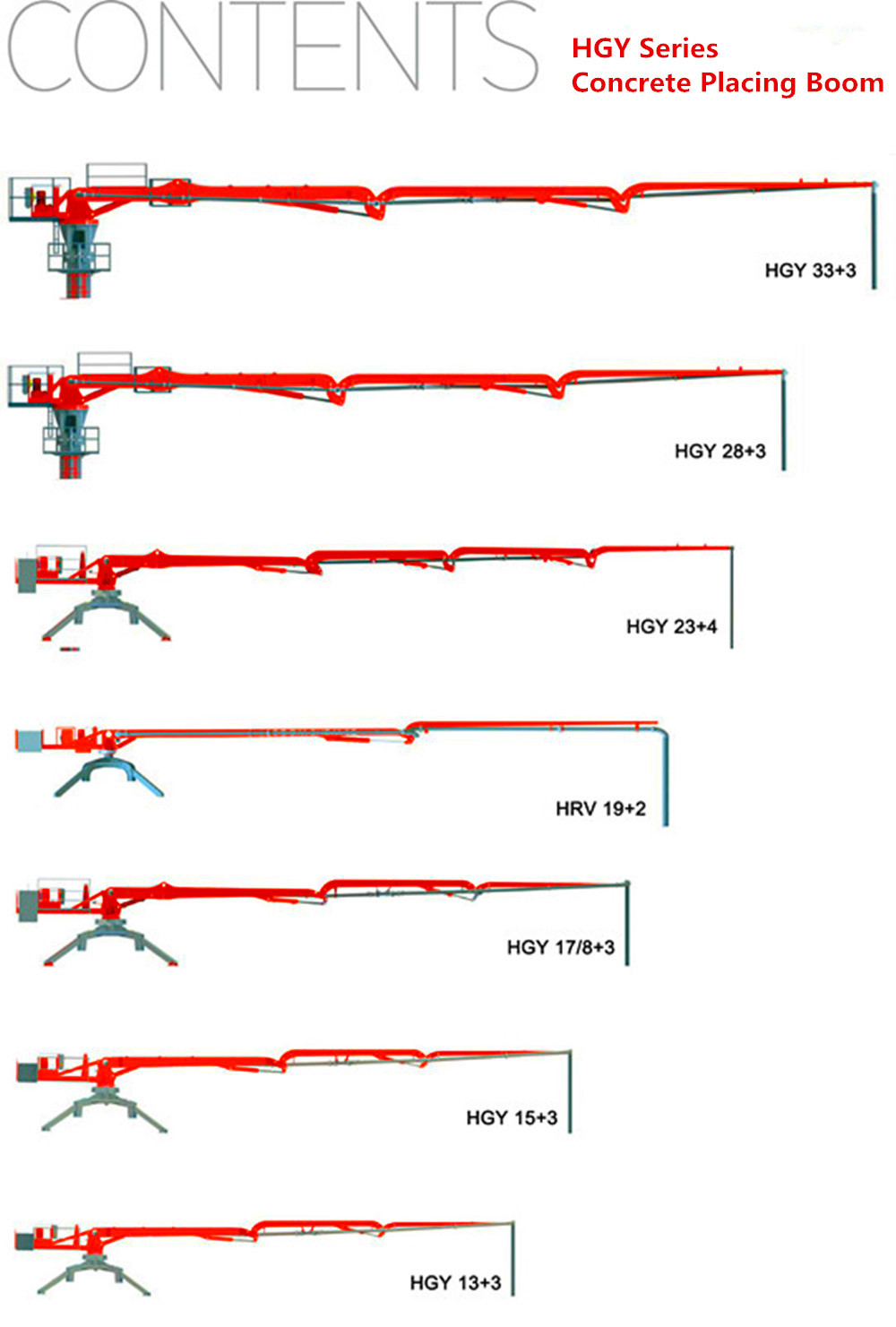

- Boom Sections

- 5 R+Z shape

- Certificates

- CE , SafeWork

- Hydraulic System Pressure

- 32 Mpa

Review

Description

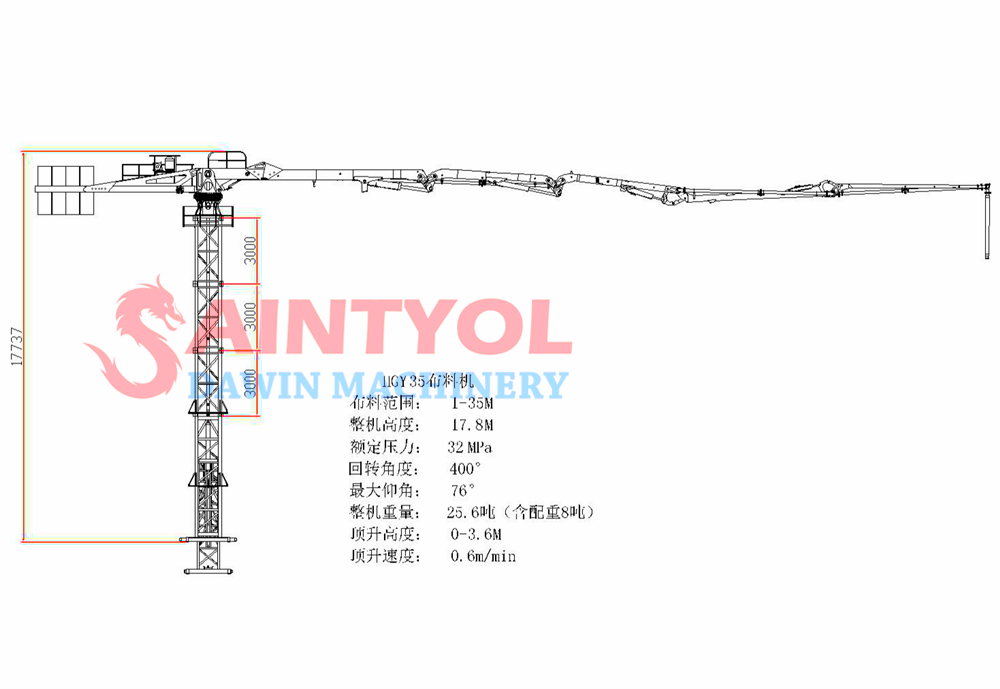

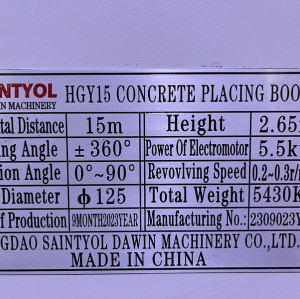

Model | HGY35 | |

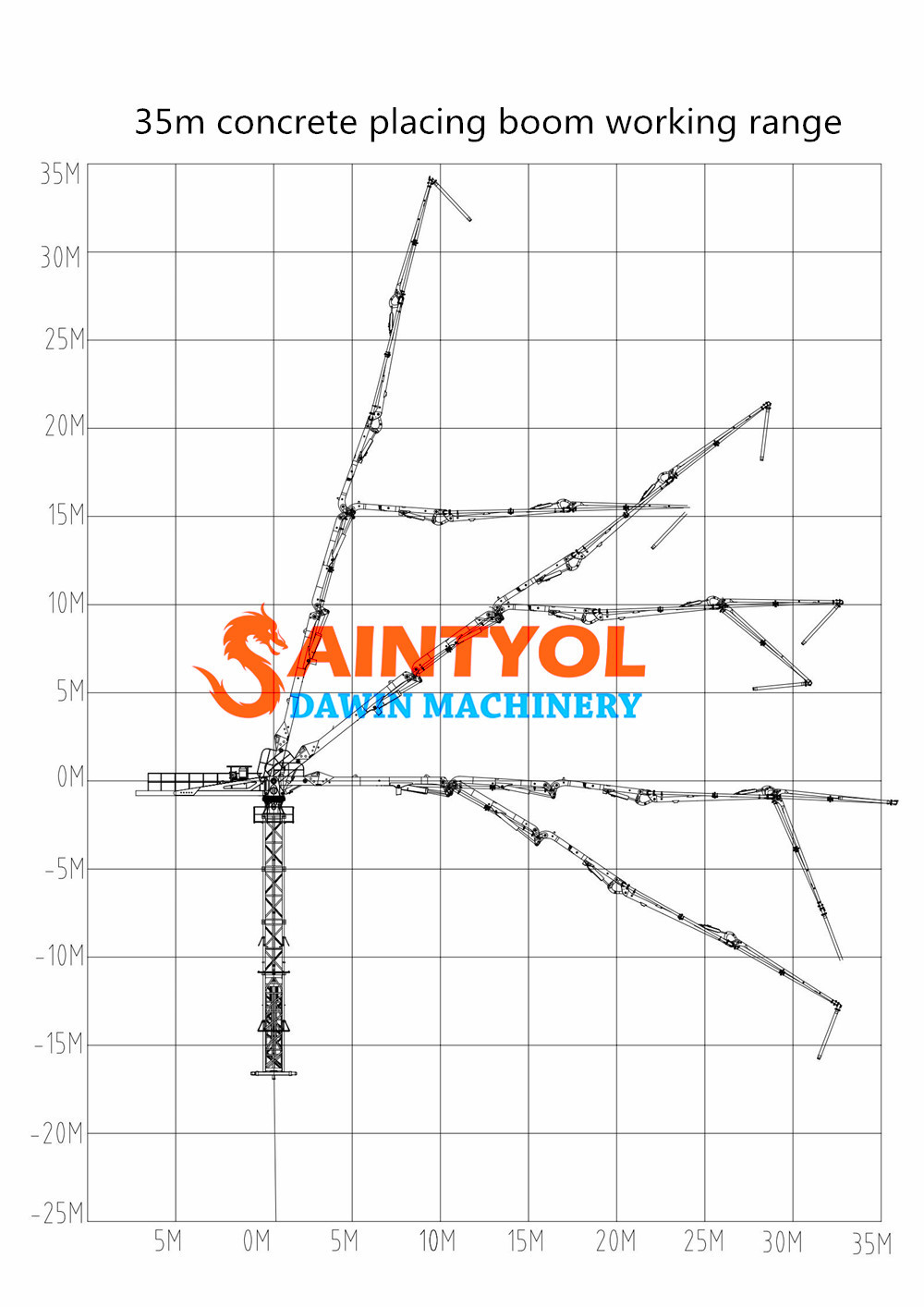

Permance | Horizontal reach(m) | 35m |

Rotation(°) | 400° | |

Swiveling speed(r/min) | 0.66 | |

Elevation angle(°) | 0~76° | |

Slewing brake | Normally closed | |

Working environment temperature | -5℃~40℃ | |

Weight(T) | 25.65 | |

Control System | Power | 380V/50HZ |

Output(kW) | 30 | |

Ptotection grade | IP54 | |

Insulation clas | F | |

System Pressure(MPa) | 32 | |

Control mode | Radio remote | |

Boom | Duct cleaning method | Wash/Dry cleaning |

Boom open way | Five (R+Z) | |

Inner diameter of delivery pipe(mm) | Φ125 | |

End rubber hose(m) | 3 | |

Length(mm) | 9880/5814/3603/7000/7000 | |

Corner(°) | 76/180/180/180/180 | |

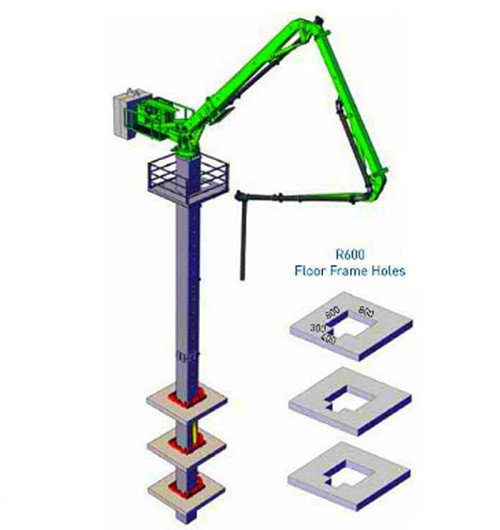

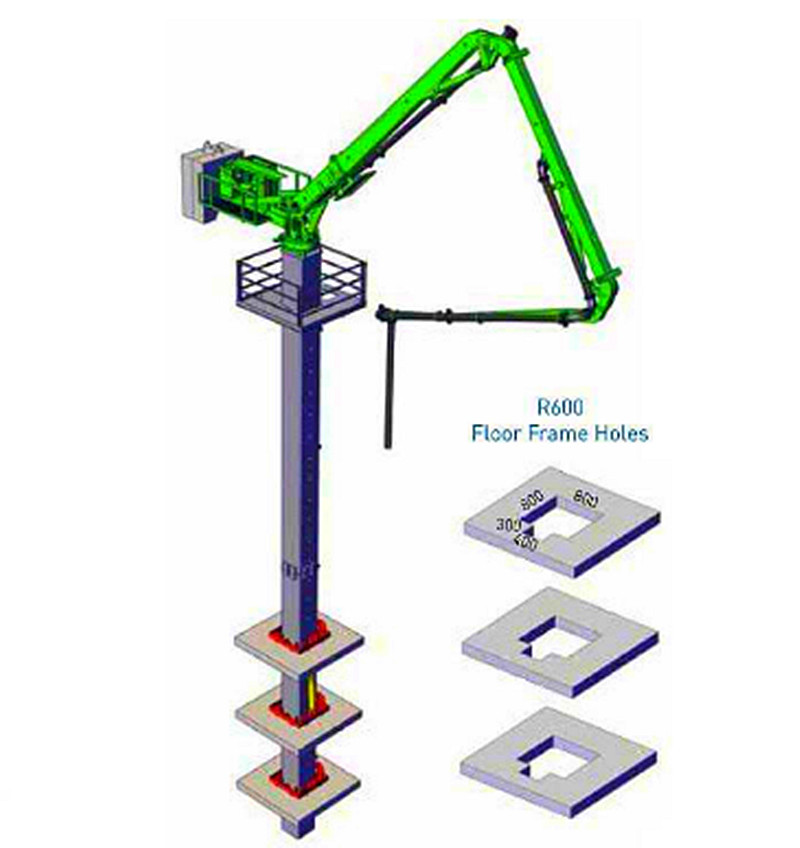

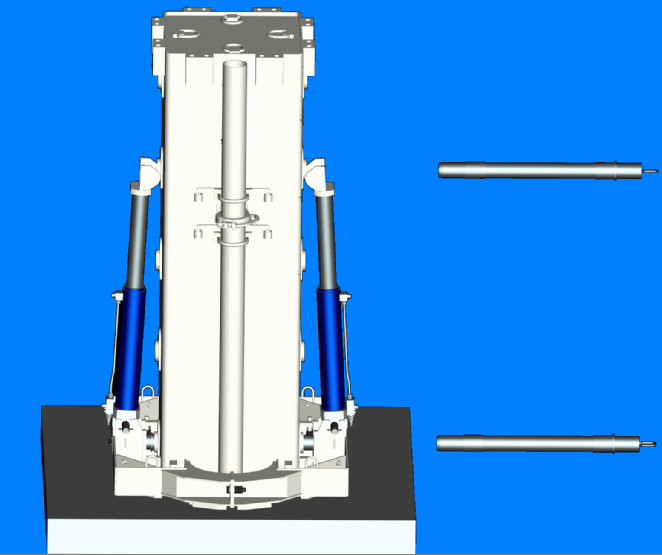

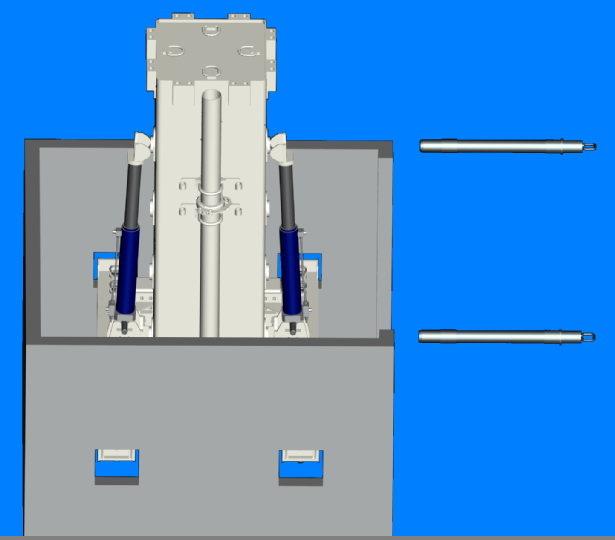

Hydraulic Jack Up System | Jack up height(m) | 0~3.6(adjustable) |

Jack-up speed(m/min) | 0-1.25 | |

Tower structure(mm) | 1200×1200(adjustable) | |

Tower Height | 14.5m | |

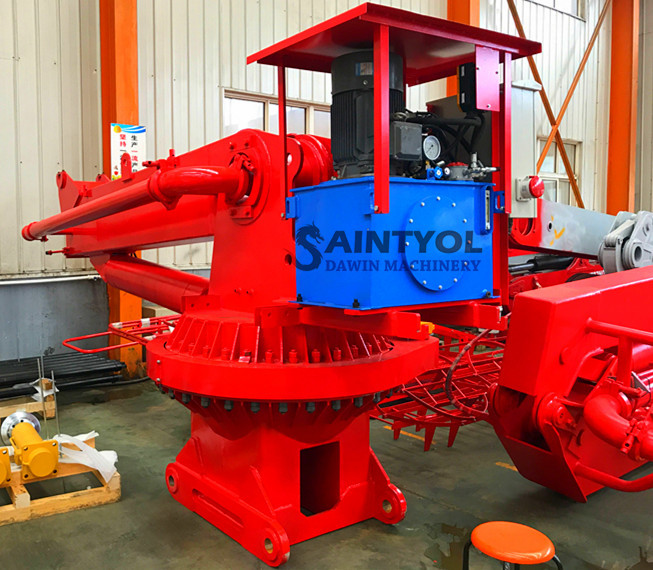

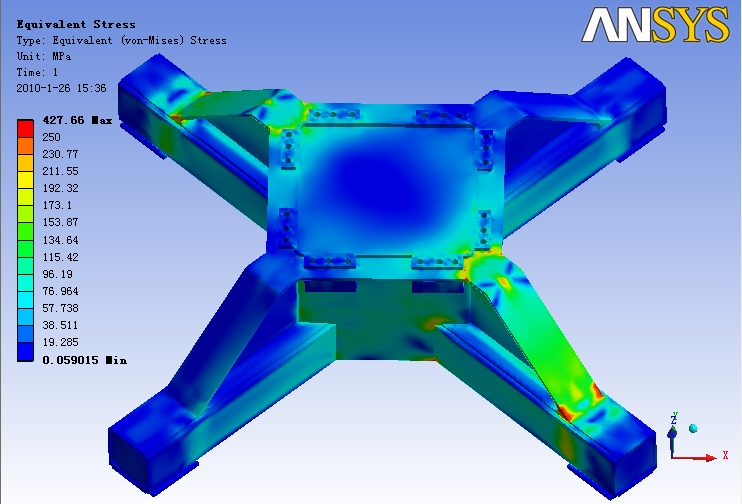

The slewing support is a large-sized bearing which connects the boom and the column, and bears the overturning moment produced by the boom. It is a key component that directly affects the whole machine’s safety. The motor redactor is from Comer in Italy. It is in a high speed rate, and long life span and reliable. The hydraulic motor can rotate the slewing table and the boom 365°through the redactor.