20m3/hr Trailer Concrete Pump With Diesel or Electric Power

- Model

- D/HBT20S

Item specifics

- Pumping Capability

- 20 cubic meter per hour

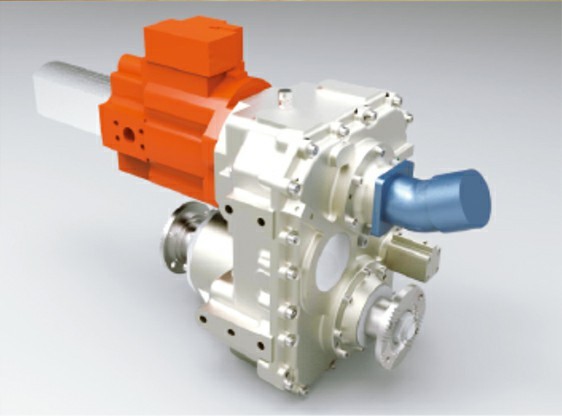

- Valve

- S shape

- Loading Hopper

- 350L

- Engine

- 39KW Yuchai Or 30KW Electric Model

- Pumping Horizontal Distance

- 400m

- Pumping Vertical

- 130m

- Delivery Pressure

- 80 Bar

Review

Description

Concrete Pump was a kind of useful and efficient concrete high pressure transport pump, widely used in highway, railway, bridge, building, tunnels, ports, water conservancy and other projects of grouting pressure, grouting mortar, concrete, large particle slurry grouting, spraying work, has the working pressure, pumping ability strong, grouting with high efficiency, smooth coating, using solid, etc.

Saintyol DAWIN Machinery Concrete pump design is light, easy to move, suitable for small and middle construction projects.

The S-valve series concrete pump is a new generation product developed by combining latest technologies both at home and abroad.

The products have passed ISO9001-2008 quality management system certification and CE certification.

Our workers strictly control all the machining processes and assembly quality, give final test to every pump by simulation working conditions and overload experiments to ensure customers zero fault as first operation.

2.The distribution valve adopts advanced S-tube valve, which has good sealing performance and simple and reliable structure.

3.The eye plate (commonly known as wear plate) and floating cutting ring are made of hard alloy, which has good wear resistance, long service life and convenient replacement. The cutting ring can automatically compensate the gap structure.

4.The machine adopts electric-liquid control mode, with perfect electro-hydraulic overload protection and instrument display system. It has anti-pump operation function, easy to eliminate blockage fault. The pumping speed can be adjusted to meet various working conditions.

5.The centralized lubrication system automatically controls the start and stop and running time by the program, effectively extending the service life of the rotating parts.

6.The electrical components such as the contactor and the push button switch are reliable in operation, the control circuit is simple, and the electrical box is equipped with a switch for easy operation.

7.The main seals are made of high quality seals to prevent internal and external leakage of the hydraulic system.

Item | Unit | Diesel Concrete pump |

Max. Theoretical Concrete Output | m³/h | 20 |

Max. Concrete Pumping Pressure | Mpa | 8 |

Distribution valve | S Valve | |

Conveying tube inner Dim | mm | 100A*70A |

Rated speed | r/min | 2300 |

Max. Teoretical Conveying Distance | m | 400/130 |

Concrete Cylinder Diameter | mm | 140*750 |

Hopper Capacity/ Filling Height | m³/mm | 0.3/1100 |

Maximum aggregate size | mm | ≦30 |

Concrete slump range | mm | 120-230 |

power | kw | 39 |

Oil tank capacity | L | 250 |

Cleaning mode | High pressure washing | |

Dimension | mm | 4100*1400*1450 |

Total Weight (including oil) | kg | 2500 |

Item (HBTS20-8-30) | Unit | Eelctric Concrete pump |

Max. Theoretical Concrete Output | m³/h | 20 |

Max. Concrete Pumping Pressure | Mpa | 8 |

Distribution valve | S Valve | |

PLC | Yes | Mitsubishi |

Conveying tube inner ID | mm | Φ100A/70A |

Rated speed | r/min | 1480 |

Max. Teoretical Conveying Distance | m | 400/120 |

Concrete Cylinder Diameter | mm | Φ140×750 |

Hopper Capacity/ Filling Height | m³/mm | 0.3/1100 |

Maximum aggregate size | mm | ≦30 |

Concrete slump range | mm | 120-230 |

Motor power | kw | 30 |

Voltage | V/Hz | 380/50 |

Hydraulic fuel tank capacity | L | 100 |

Cleaning mode | High pressure washing | |

Dimension | mm | 4100*1500*1600 |

Total Weight (including oil) | kg | 2200 |