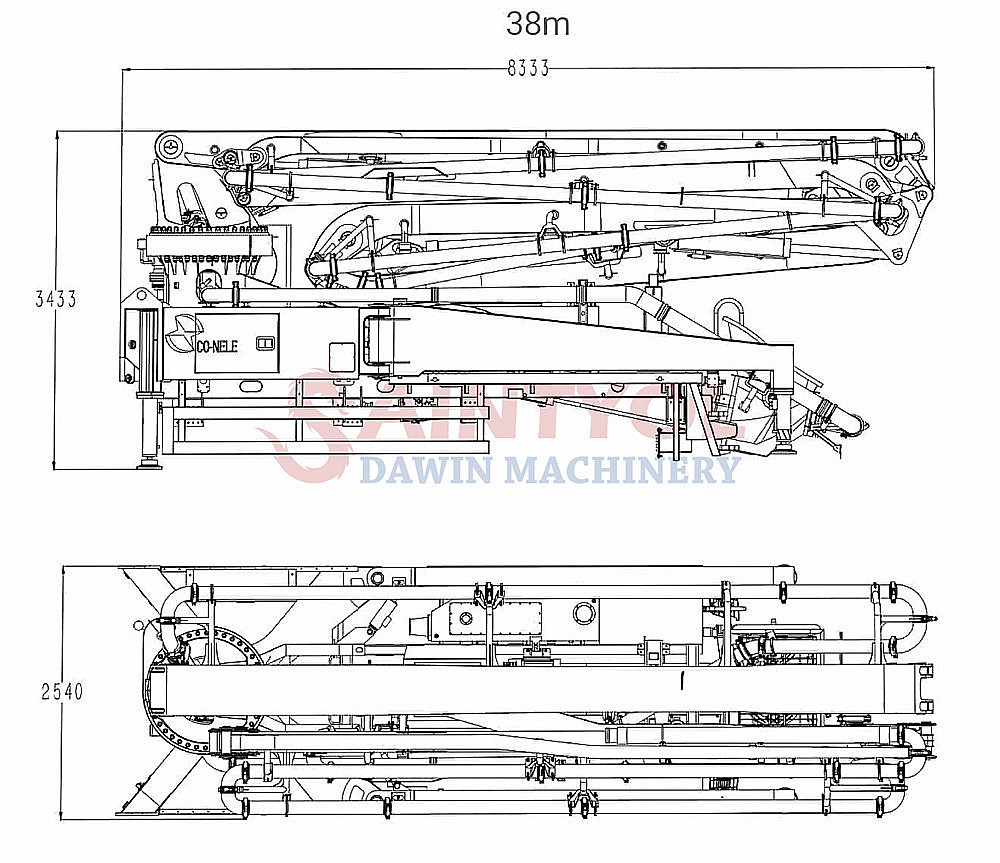

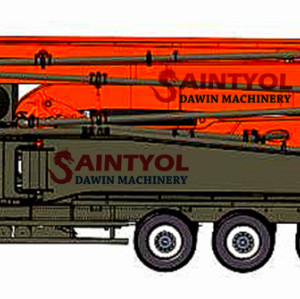

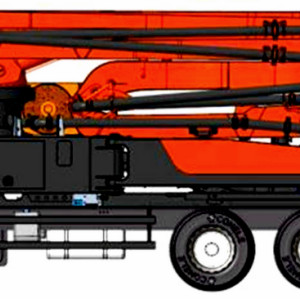

Upper Part Supersture38m 5RZ Truck Mounted Concrete Boom Pump Without Truck Chassis

- Model

- KNL5232THB 38-5RZ

Item specifics

- Max. Theor. Output(high/low pressure)

- 66/111 Mpa

- Rated Working Pressure

- 32Mpa

- Oil Cylinder Dia.×Stroke

- φ125×1650

- Concrete Cylinder Dia.×Stroke

- φ230×1650

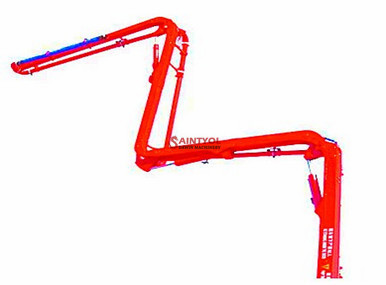

- Placing Boom Structure Type

- 38-5RZ

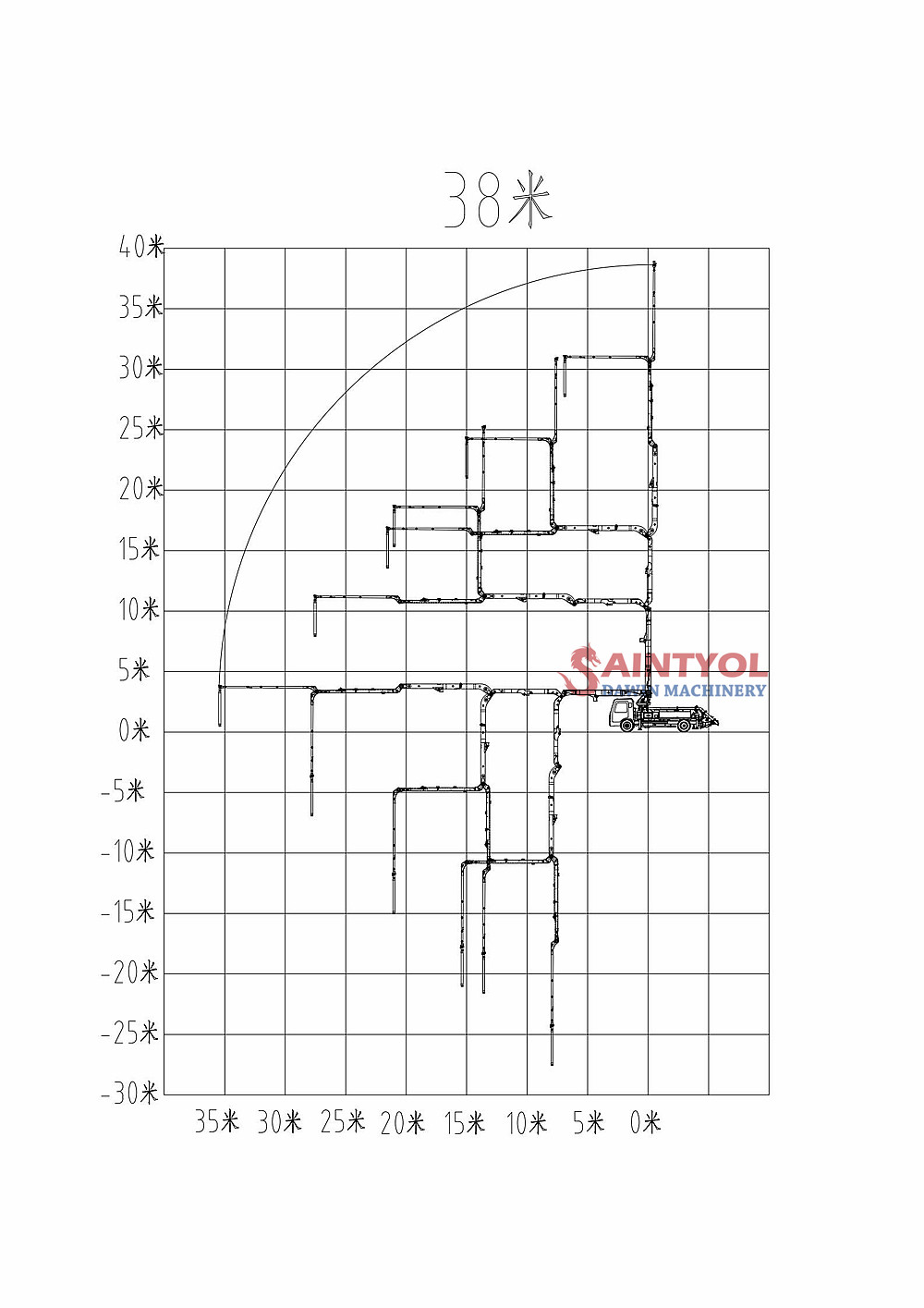

- Max. Placing Height

- 37.3

- Horizontal Placing Radius

- 33.5

- Placing Depth

- 29.5

- Chassis Model

- HOWO, ISUZU, Benz etc

- Drive Direction

- Left or Right in option

Review

Description

Customized specialized 38 meter remote control truck mounted concrete boom pump( without chassis) is combined with high reliability, economy, safety and durability.It has reasonable collocations for the chassis system, power system, control system, hydraulic system and pumping system. With the characteristics of flexible fold able arms, little space occupying support legs, easily movable chassis, equipped with H/L pressure switch, high outlet pressure, the whole concrete pump truck. 38 meter remote control concrete pump truck is more flexible, reliable, stable and safe. It is the top-choice concrete equipment widely used in tunnel, airport, seaport, high-speed rail site, beam field, bridge construction projects and so on.

As different country has different requirement on the truck, if you have truck in hand, that’s also available only selling our concrete boom pump without truck.

Concrete pump truck is the refined product after trailer concrete pump,concrete line pump, HGY hydraulic concrete placing boom, and it is the high efficient concrete conveying equipment integrating concrete pumping and placing. The boom covers high reliability, economy, safety, durability, owing reasonable matching of chassis, power, electric control and hydraulic pump system.

型号 Model | KNL5232THB 38-5RZ | ||

项目 Item | 单位 Unit | 值 Parameter | |

泵送系统 Pumping System | 最大理论输送量 (高压/低压) Max. Theoretical Concrete Output (H/L Pressure) | m3/h | 66/111 |

混凝土最大出口压力 (高压/低压) Max. Theoretical Output Pressure (H/L Pressure) | MPa | 9.5/5.6 | |

额定工作压力 Rated Working Pressure | MPa | 32 | |

泵送频率 (高压/低压) Pumping Frequency (H/L Pressure) | min-1 | 16/27 | |

料斗容积 Hopper Capacity | L | 600 | |

上料高度 Feeding Height | mm | 1400 | |

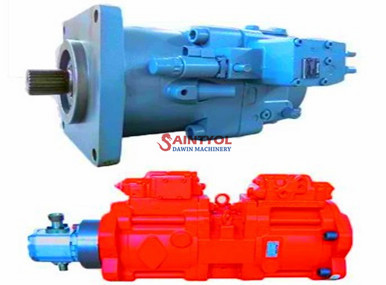

液压系统型式 Hydraulic System Mode |

| 开式 Open Loop | |

分配阀形式 Distribution Valve Mode |

| S管阀 S Valve | |

油缸缸径×行程 Oil Cylinder Diameter × Stroke | mm | Φ125×1650 | |

混凝土缸径×行程 Concrete Cylinder Diameter × Stroke | mm | φ230×1650 | |

液压油冷却 Hydraulic Oil Cooling |

| 风冷 Air Cooling | |

推荐塌落度 Recommended Concrete Slump | cm | 12~23 | |

最大骨料尺寸 Max. Aggregate Dimension | mm | 40 | |

臂架 Placing Boom | 结构形式 Structure Type |

| 38-5RZ |

最大布料高度 Max. Placing Height | m | 37.3 | |

最大布料半径 Max. Placing Radius | m | 33.5 | |

最大布料深度 Max. Placing Depth | m | 29.5 | |

回转角度 Slewing Angle |

| ±270° (540°) | |

输送管直径 Delivery Pipe Diameter | mm | 125 | |

末端软管长度 End Hose Length | mm | 3000 | |

臂架最小打开高度 Min. Height Of Opening Placing Boom | mm | 9500 | |

支腿跨距(前×后×纵向) Outriggers Span (Front × Rear × Side) | mm | 6270×7890×7046 | |

底盘及整车Chassis & The Whole Machine | 底盘型号 Chassis Model |

| ZZ5235N5213F1 |

轴距 Wheelbase | mm | 5200 | |

发动机型号 Engine Model |

| MC07.31-60 | |

发动机额定功率 Engine Rated Power | kW | 228 | |

燃油箱容积 Fuel Tank Volume | L | 400 | |

尾气排放标准 Tail Gas Exhaust Standard |

| 国VI EURO VI | |

整车外形尺寸 (长×宽×高) Overall Dimension (L x W x H) | mm | 10560x2550x3740 | |

其它Others | 润滑方式 Lubrication Mode |

| 手动液压两用同步润滑泵 Manual Hydraulic Dual Purpose Synchronous Lubricating Pump |

液压油箱容积 Hydraulic Oil Tank Volume | L | 500 | |

控制方式 Control Mode |

| 手动+遥控 Manual+Remote Control | |

压力水箱最大压力 Max. Water Tank Pressure | MPa | 0.8 | |

水箱容量 Water Tank Volume | L | 400 | |

混凝土管清洗方式 Concrete Pipeline Cleaning Mode |

| 水洗/干洗 Water/Dry Cleaning | |