21m Diesel Engine Mounted Indoor Mobile Placing Boom Pump With Self-Made Chassis

- Model

- KNL5140THB

Item specifics

- Pumping Capability

- 50m3/hr

- Rated Working Pressure

- 32Mpa

- Oil Cylinder Dia.×Stroke

- φ100×1400

- Concrete Cylinder Dia.×Stroke

- φ230×1400

- Placing Boom Structure Type

- 21-3R

- Max. Placing Height

- 21

- Horizontal Placing Radius

- 17

- Placing Depth

- 10.6

- Mounted Engine

- LOVOL 1004 56KW

- Drive Direction

- Left or Right in option

Review

Description

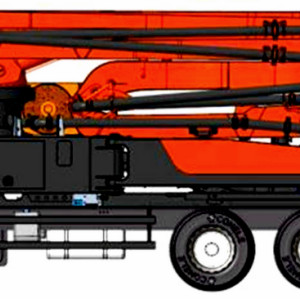

1.Diesel mobile concrete placing boom pump adopted self-made chassis, no need the number plate. It is the non-standard machine with easier marketing procedure and without high import tariff.

2.The chassis can be hydraulic driven, speed change, shift and steering by the hydraulic motor, gearbox and oil cylinder, and also can be driven by motor tractor.

3.Through finite element analysis, dynamics analysis, calculation and experiment, on the basis of accurate data support, adopted high strength low alloy steel plate, all materials and welds pass 100% NDT. Ensure the rationality and reliability of the X-type brace and arm structure.

4.The engine speed is controlled automatically, when the arms moving the rev is 1100-1200rpm, when pumping, the rev changes with the displacement between 1200-1700rpm, low rev with low displacement while high rev with high displacement. The engine torque is the largest during this rev range, so that the fuel is economical and efficient.

Model | KNL5140THB | ||

Pumping System | Unit | Parameter | |

Max. Theoretical Output | m3/h | 50 | |

Max. Theoretical Output Pressure | MPa | 8 | |

Rated Working Pressure | MPa | 32 | |

Pumping Frequency | min-1 | 18 | |

Hopper Capacity | L | 600 | |

Feeding Height | mm | 1350 | |

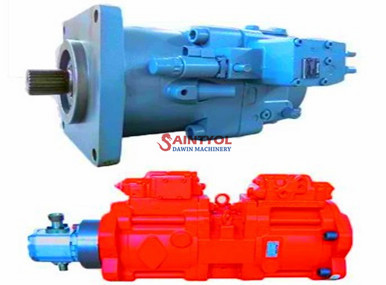

Hydraulic System Type | Open Loop | ||

Distribution Valve | S Valve | ||

Oil Cylinder Diameter × Stroke | mm | Φ100×1400 | |

Concrete Cylinder Diameter × Stroke | mm | φ230×1400 | |

Hydraulic Oil Cooling | Air Cooling | ||

Recommended Concrete Slump | cm | 12~23 | |

Max. Allowed Aggregate Dimension | mm | 40 | |

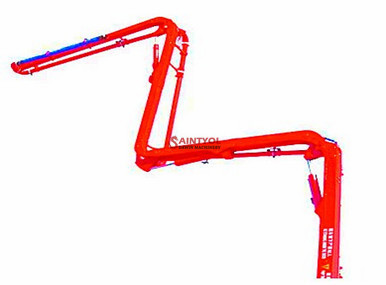

Placing Boom | Structure Type | 21-3R | |

Max. Placing Height | m | 21 | |

Max. Placing Horizontal Distance | m | 17 | |

Max. Placing Depth | m | 10.6 | |

Slewing Angle | ±270° (540° ) | ||

Pipe Diameter | mm | 125 | |

End Hose Length | mm | 3000 | |

Min. Height Of Opening Placing Boom | mm | 7000 | |

Outriggers Span (Front × Rear × Side) | mm | 4024×3100×5227 | |

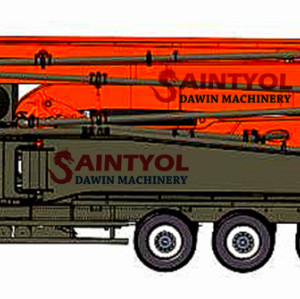

Chassis And The Whole Machine | Chassis Model | Saintyol DAWIN | |

Wheelbase | mm | 4700 | |

Engine Type | 4BTA3.9-C130 | ||

Engine Power | KW | 97KW | |

Fuel Tank Volume | L | 150 | |

Tail Gas Exhaust Standard | EURO II | ||

Overall Dimensions (L x W x H) | mm | 10540x2320x3570 | |

Others | Mobile Type | Self Move or Towing | |

Lubrication Mode | Manual Hydraulic Dual Purpose Synchronous Lubricating Pump | ||

Hydraulic Oil Tank Volume | L | 500 | |

Control Mode | Manual+Remote Control | ||

Maximum Water Tank Pressure | MPa | 0.8 | |

Water Tank Volume | L | 300 | |

Concrete Pipeline Cleaning Mode | Water/Dry Cleaning | ||

1.Adopted self-made chassis, no need the number plate. It is the non-standard machine with easier marketing procedure and without high import tariff.

2.The mobile placing boom pump chassis can be hydraulic driven, speed change, shift and steering by the hydraulic motor, gearbox and oil cylinder, and also can be driven by motor tractor.

3.Through finite element analysis, dynamics analysis, calculation and experiment, on the basis of accurate data support, adopted high strength low alloy steel plate, all materials and welds pass 100% NDT. Ensure the rationality and reliability of the X-type brace and arm structure.

4.The engine speed is controlled automatically, when the arms moving the rev is 1100-1200rpm, when pumping, the rev changes with the displacement between 1200-1700rpm, low rev with low displacement while high rev with high displacement. The engine torque is the largest during this rev range, so that the fuel is economical and efficient.

5.Dual synchronous lubricating system. when working, the swing valve control oil drive, when not working, can push the rocker manual lubrication. Circulation port can be a bearing size hopper seat lubrication, synchronization can be sent to the piston pump, the piston’s life increased to above 30 thousand cu meters.

6.The placing boom arm frame adopts the load sensing proportional multi way valve, the movement speed is stepless regulation, the speed is easy, the operation performance is excellent. Not only can realize the remote control, but also can realize the emergency manual operation. Mixing and supporting legs by the gear pump oil, with the pressure relay can achieve automatic mixing and reverse, to prevent large stones stuck blade.