Saintyol DAWIN tells you how to prevent rollover of small concrete pumps?

- Share

- From

- Saintyol DAWIN News Center

- publisher

- Jenny

- Issue Time

- Apr 19,2022

Summary

At present, a kind of mechanical equipment that many construction parties use a lot - a small concrete pump, which greatly improves the construction efficiency. If the pump driver does not operate properly in the project, it is easy to cause the pump to roll over, which is a problem that many construction parties are very concerned about. So, how can the small concrete pump truck prevent rollover?

At present, a kind of mechanical equipment that many construction parties use a lot - a small concrete pump, which greatly improves the construction efficiency. If the pump driver does not operate properly in the project, it is easy to cause the pump to roll over, which is a problem that many construction parties are very concerned about. So, how can the small concrete pump truck prevent rollover?

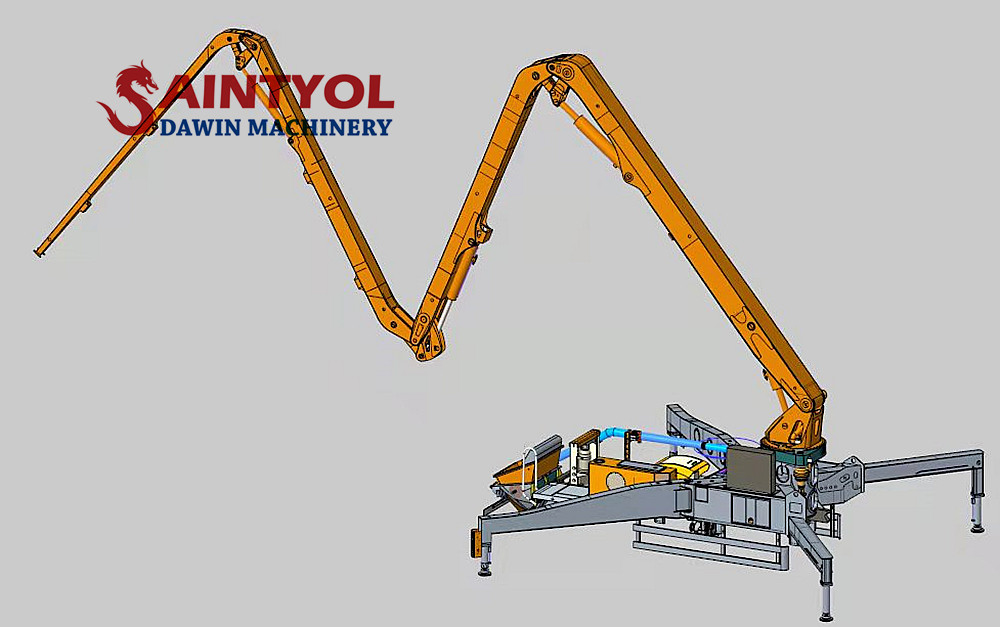

Experts pointed out: The main purpose of the boom of the small concrete pump truck is for distribution. During normal distribution, the boom posture needs to be changed constantly. The settlement may also change the center of gravity of the vehicle, and the center of gravity deviates from the range of the outriggers, which will cause the vehicle to tip over. In the daily use process, more attention should be paid. At present, major host manufacturers have added intelligent anti-overturning measures more or less, aiming at the problem of how to prevent the rollover of small concrete pump trucks. Specifically, these measures are mainly divided into into two categories:

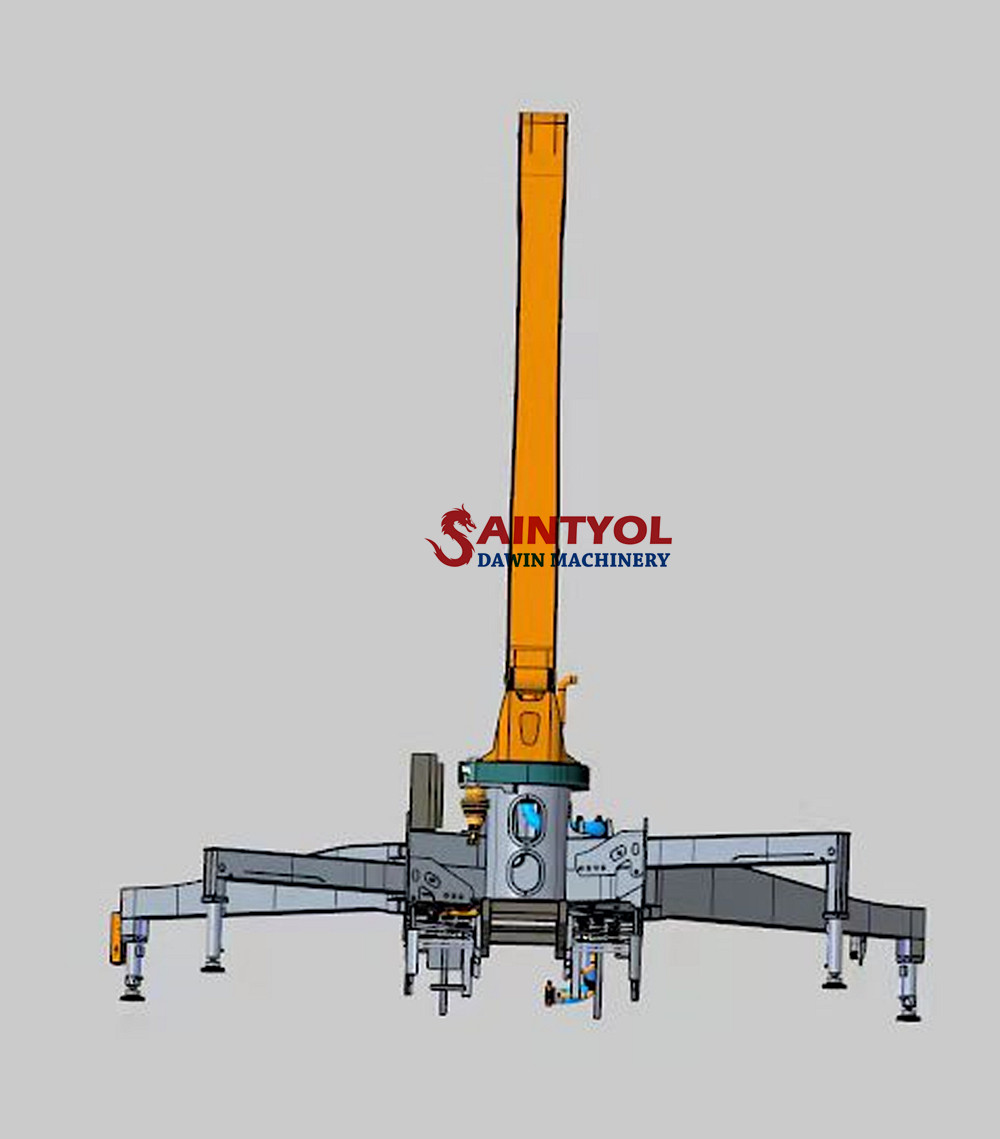

1. The outrigger force sensor detects the force of each outrigger in real time, and when the force of the two outriggers on a side is less than a certain value, a warning is issued in time or the current action is terminated. What needs to be added is that artificial intelligence is never omnipotent. This kind of axial gravity sensor can only sense the force in a certain direction. Due to the shaking of the whole vehicle and the different verticality of the outriggers during pumping, the detected force The authenticity is not enough, and there is the possibility of false signals and missing signals.

2. The inclination device for detecting the levelness of the whole vehicle and the sensor for detecting the force on the outriggers. The inclination sensor can sense the levelness of the whole vehicle and send the level angle information in real time, which can effectively avoid the overturning of the whole vehicle caused by the slow subsidence of the ground. The function of the inclination sensor is to measure the inclination angle of the whole vehicle in real time. Inclination sensor measurement accuracy is higher than 0.05 degrees. It can filter out the tiny tremors caused by the vibration of the engine and the pump, and trigger an alarm when the left and right angles are greater than 3 degrees or the front and rear inclination angles are greater than 5 degrees.